Shue’s stunning achievement – besting 468 of the world’s finest military and industry marksmen to take his first Gold in 2017 at historic Camp Perry and besting more than 500 marksmen in 2018 – shows you what can happen when preparation meets opportunity. For Shue, that preparation began years ago when he enlisted in the Marine Corps just months after the devastating attacks that rocked America on 9/11. He was 21 years old and working in mechanical engineering. “The military was never a goal of mine,” Shue recalls, “but I wanted something more. The whole world shifted for me.”

Military training developed Shue’s raw skills and mental discipline, and he soon became a marksmanship coach for the Marines. This demanding role required Shue to qualify as an expert sharpshooter himself and demonstrate a thorough knowledge of firearms handling, safety, and range management. More importantly, being an instructor taught Shue to pinpoint and correct the mistakes that could cost a soldier dearly on the battlefield, knowledge that he used to improve his own proficiency as a marksman.

Returning from a deployment, Shue had the opportunity to qualify for the Marine Corps Shooting Team. It was his first taste of competitive shooting, and he was hooked. He moved from Okinawa to Quantico with a new mission: “Now your job is to ‘learn the gun’,” he said. “For the next five years, my job was to get up and be the best at this one thing, all day long, week after week.” That discipline, honed through years of day-in, day-out consistency and training, served Shue well. Before long, he had won just about every Marine Corps shooting prize there was, and after he left the military, he kept competing – and winning.

Shue’s performance caught the attention of Team Cabot not long afterward, and he was introduced to the company by Cabot shooter Willliam Bethards at Shot Show in 2015. Shue says he was immediately impressed with Cabot’s family-oriented culture and, of course, the quality of their firearms.

As a mechanical engineer and custom gunsmith who owns his own machining firm, Shue has a sharp eye for superior design and craftsmanship. “When I handled my first Cabot gun, I was practically giddy — ‘I get to measure this!’,” he laughs, “and I went super-nerd over how it was put together. There isn’t a gun on the planet that’s tighter than a Cabot.”

With the whirlwind of winning the back-to-back NRA Nationals behind him, Shue is back home in North Carolina, doing what got him to the top: train, train, and train some more. The next competition is always around the corner, and the thrill of victory comes only for those willing to put in the mental preparation and grueling practice that takes place away from the spotlight.

It’s not unusual for Shue to rack up thousands of trigger pulls dry-firing for every actual round he sends downrange. For novice shooters looking to improve their competition stats, that’s his first piece of advice: “Dry fire. Dry fire. Dry fire,” he says. “It costs you nothing but time. My biggest jump in performance was when I was doing a whole lot more dry-firing than actual firing.”

Second, he says, go to the range and talk to other shooters. “We all started at the bottom, and everyone can help you,” he says. “A lot of people will even offer to let you try one of their guns. Talk to the people who are doing what you want to do, and ask their advice.”

And his third piece of advice is, have a plan and never quit. “Don’t get frustrated,” Shue says. “You need to have a goal, whether it’s winning Nationals, going to the Olympics, whatever. You’ve got to have a plan to get there. And never stop striving to become better at what you do.”

William Bethards has been World Class Shooter for over 25 years. His specialty disciplines are Conventional and International Rifle and Pistol Competition Shooting.

William Bethards is a Retired Marine Master Sergeant and Former Virginia State Trooper. He is currently a FBI Law Enforcement Specialist. Actively Instructing new FBI Trainees and current FBI agents in Marksmanship Fundamental, and Tactics and Staff member at Ballistic Research Facility.

This World Class Shooter has now turned his attention back to the competitive shooting world.

He has starred in History Channel’s Hit Reality TV Show, Top Shot Season 4.

A list William’s accomplishments as a competitive marksman are as follows:

1. FBI Law Enforcement Specialist. (2004 – Present)

2. FBI Advanced Firearms Instructor

3. NRA FBI Pistol Shot National Record Holder 22/45/CF. (2010)

4. Virginia State Trooper Top Shot Award. (2002)

5. Retired USMC Master Sergeant (1981-2002)

6. United States Marine Corps Shooting Pistol Team SNCOIC (1999-2002)

7. Gold Cup National Champion Camp Perry. (1988)

8. 6 Time Presidents 100 recipient. (National Championships).

9. NRA National Record Holder .22 Cal Pistol. (1995)

10. Double Distinguished Rifle & Pistol Shooter. 1986 (P) 1989 (R)

11. (High Master) Conventional & International Shooting Classifications

12. NRA 2650+ Aggregate Club Shooter Conventional Bull’s-eye Shooter.

13. Conventional & Internationally known Shooter.

14. Gold Medal Lauchheimer Winner. ( USMC Top Shot Rifle & Pistol (1995)

15. NRA Service National Pistol Champion. (1995)

16. Double Distinguished Rifle and Pistol Marksmen 1986 (P) 1989 (R)

17. United States Olympic Team Qualifier. (1995) Olympic Tryouts Tampa FA.

18. USMC Shooting Team Member (1987-1990) & (1994 -1996) & (1999-2002)

19. Top Shot Season 4 Star (2011-2012) History’s Behind the Bullet (2012)

20. History’s Top Shot All Stars Season 5 (2012-2013)

21. Sponsored Shooting Team Member of Cabot Guns. (2012- Present)

Just to Name a Few.

Otto Carter is the master engraver who created the unique artwork featured on three of our pistols: Pandemonium, The Legend of Sacromonte and The Sixth Commandment. They all received extensive praise from connoisseurs of firearms as well as admirers of the engraver’s craft. We thought it would be interesting to learn how Otto came to be such a top-flight artisan.

Otto Carter is the master engraver who created the unique artwork featured on three of our pistols: Pandemonium, The Legend of Sacromonte and The Sixth Commandment. They all received extensive praise from connoisseurs of firearms as well as admirers of the engraver’s craft. We thought it would be interesting to learn how Otto came to be such a top-flight artisan.

With an art degree in hand from Abilene Christian University, Otto started his career as an apprentice sign painter. Painting signs was a practical way to hone his manual skills and develop skills in graphic design. Importantly, it introduced him to drawing scrolls, an integral design element for an engraver.

His early attempt at metal engraving was learning experience. Interested in the art engraving, he ordered an instructional VHS tape on basic engraving and a set of inexpensive tools.

Frustrated by his first attempts, he put the tools away and resolved not to try again until after he had studied with someone experienced. “You have to learn this the right way or you won’t ever be any good at it,” Otto said. He eventually took a week-long course on engraving that set him up with good basic skills, such as chisel sharpening and cutting techniques.

From there, Otto recounted his interest in metal engraving as an experience of ever-increasing engrossment. “I ruined a few good guns,” he said with a chuckle. “But I was on my way.” He devoted himself to becoming an expert on scrollwork, which Otto described as absolutely essential. Once you master standard scrolls, he said, you can branch out with a variety of styles and themes.

Friends started to ask him to embellish motorcycle parts and engrave guns. After a lot of diligent work, his work caught on and he became marketable as a paid artisan. His work on a motorcycle fuel tank was so elaborate and impressive that his work quickly became prized by motorcycle enthusiasts world-wide.

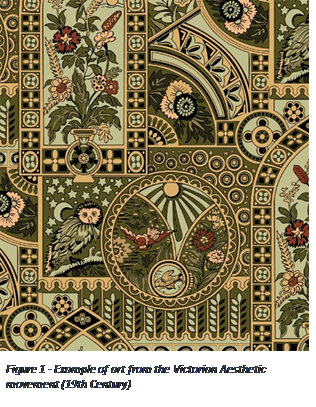

He learned to emulate the Victorian Aesthetic Movement style he had long admired. The Aesthetic Movement, which was hugely popular in the mid-19th Century, emphasized motifs of a variety of cultures included into a single design. The style is strongly represented in both the Pandemonium and The Legend of Sacromonte guns.

Looking at the engraved surfaces of the guns, it’s natural to wonder how Otto is able to realize such finely-detailed designs. One factor is his use of a stereo microscope while making his marks on the metal. This is a technique and toolset similar to that used by ophthalmic surgeons removing cataracts or brain surgeons sewing together blood vessels. The work looks much larger than it actually is, enabling Otto to make tiny movements with his engraving tools to create intricate designs. “I think like a painter but work like a surgeon,” Otto said.

Looking at the engraved surfaces of the guns, it’s natural to wonder how Otto is able to realize such finely-detailed designs. One factor is his use of a stereo microscope while making his marks on the metal. This is a technique and toolset similar to that used by ophthalmic surgeons removing cataracts or brain surgeons sewing together blood vessels. The work looks much larger than it actually is, enabling Otto to make tiny movements with his engraving tools to create intricate designs. “I think like a painter but work like a surgeon,” Otto said.

Otto does not use computer-aided engraving technologies. In a technique he described as “painting meets carving,” he creates designs in metal with (harder) metal tools. He does take advantage of digital technology, however. His typical process involves creating a master version of the design on paper, usually in a larger size than it will be on the gun itself. Then, with the use of a scanner and printer, he creates a miniaturized, transferrable version of the design on acetate. After transferring the image onto the gun’s metal surface through a burnishing process, he can then see clearly through the microscope where he has to cut. Each of his engraved Cabot pistols took hundreds of hours to engrave. If he made even a single mistake along the way, the work would have been ruined.

The gold inlays seen in the guns was crafted through a painstaking process. He first carves a thin cavity into the areas that will have the inlay. He then takes a chisel and cuts a dovetail around the inside edge of the cavity and proceeds to chisel a cross-hatched pattern in the bottom. This securely traps the gold in the recess. Rows of gold wire are hammered into the space with a brass punch. The hammering forge welds the gold into a homogenous shape. It is then sanded flush or sculpted as desired.

Otto’s work is a unique fusion of the painter’s art with the intense, laborious process of metal engraving. We are so excited to have had the chance to work with Otto and provide a showcase for his immense talents. See Otto’s work on Cabot one-of-a-kind pistols, Pandemonium, The Legend of Sacromonte and Sixth Commandment.

A selection of Otto’s Work

When we first met Jason, we knew he was a kindred spirit for Cabot Guns. Like our team, he’s committed to excellence and outstanding creativity in his art. Also, like us, he honors the traditions of his field.

In fact, one of the first things that strikes you when you talk to Jason is the homage he pays to his teachers and the ancient lineage of his craft. Before he tells you about his work, he will tell you that he studied under the bladesmiths Don Fogg, Rick Dunkerley, Jim Crowell and Steve Schwarzer and metalsmiths Tim Mcreight , Peter Ross and Steven Yusko. He’s humble, though it’s worth pointing out that Jason has earned numerous awards and published extensively about his work. He’s highly sought after as an instructor in metalsmithing and glass blowing. In our opinion, Jason is the greatest artisan in the world in the field of creating unique breathtaking patterns in Damascus steel.

Jason was born and raised in Vermont, earning a BFA in Metalsmithing and Jewelry from Maine College of art in 1998. He now lives on the coast of Maine in an environment he finds very suitable to his temperament and pursuit of unique artistic creations. His work has been published in 20 international books in the decade that followed.

He continues his studies, though, at craft schools like Haystack and New England school of Metalwork. Jason is in a league of his own in pattern welded steel and damascus. Jason describes himself by saying, “I’m always a student, continually trying to improve my skill set and apply my techniques to different objects.”

The Morrissey portfolio spans hammers, holloform and solid glass pieces, glass, jewelry, knives and marbles. As he puts it, “Making knives, hammers and other tools in such a permanent material is very rewarding. The fact that these objects have the potential to become artifacts is very appealing and rewarding.”

His work has one continuous defining quality: they’re all absolutely stunning. His hammers feature the same type of damascus designs as we employ in Cabot pistols. His highly unusual collection of knives are comparably dazzling. He explains that studying and applying glass techniques has allowed him to visualize what’s going on inside the pieces of steel. His patterns are inspired by fossils, marine life, ancient writings and texts and otherworldly things.

Jason enjoyed the challenging of trying to place mosaic patterns strategically on the grips after they went through machining. “There were a lot of man hours grinding, cutting, fitting to make and achieve the crispness of these patterns.” He is grateful for the help he received from his shop mates at the Evergreen shop.

Damascus steel was used for sword blades in the Near East dating back as far as the 3rd century. The origins are thought to be in India. A Damascus blade has distinctive patterns of banding and mottling which can look like a fluid design on the surface of the metal.

Named after Damascus, the capital city of Syria, Damascus swords were considered tough and shatter-resistant. Damascus steel is the stuff of legends, with ancient swords able to cut through a falling human hair or even a rifle barrel. Though modern steel alloys are stronger, Damascus blades were truly extraordinarily durable in their era.

The original method of producing damascus steel is not known. Today, the damascus technique involves welding together many thin layers of metal, usually from two or three distinct types of steel. The stack of metal strips is formed into a billet, or white-hot block of steel. The metalsmith then hammers the billet until it is flat and smooth. After polishing, the steel piece looks like any other flat, shiny piece of metal. However, under the surface lays a pattern caused by the layering of metals.

Using an acid etching process, the metalsmith can reveal the underlying pattern. The etching technique is up to the artisan. There are an infinite number of possibilities. This is where Morrissey’s training and talent comes through. In his work for Cabot Guns, Morrissey adapted techniques he learned in cane glass blowing and Millefiori to create beautiful patterns on the grips and slides of our 1911 gun.

We like to work with artists who can bring a combination of talent, vision and craftsmanship to the creation of an exceptional collector’s firearm. We were fortunate to partner with Brian Engel, a noted glass artist, on our Crystal Gun, which features grips made from handcrafted lead crystal and a glass Tristar trigger. When you see hand the-cut diamonds and other fine details of the Crystal Gun, you realize you are in the presence of superior artistry.

Brian grew up in southwest New Mexico, in what he calls “the back country.” His early life was full of outdoor activities like camping, fishing, hunting and horseback riding. This start gave him a lifelong appreciation of the outdoors and the beauty of nature—a theme he explores continually in his creative work.

Becoming a glass artist was not what Brian had in mind as a young man, however. After serving four years as a shipboard firefighter in the US Navy, Brian went to school to study forestry in New Mexico. This was his dream. He was interested in fire science. After multiple injures while working for the forest service he was advised to avoid further damage to his body. Brian realized he needed to change careers.Using GI Bill benefits, he enrolled in art school, earning a BFA in glass from Southern Illinois University. One of his mentors there was Jiyong Lee, an artist and professor known for “Segmentation Series,” glassworks that emulate cellular division in life sciences. Brian credits Lee with teaching him the challenging techniques of cold glass work. You can see Lee’s influence in Brian’s work, as exemplified by the “Green Cylinder Segmentation” shown in the figure.

nspired by his early adventures, Brian’s glass work frequently depicts abstracted landscapes that feature thick blown glass forms that are subsequently cut and polished. He makes use of shape, texture and light to highlight the unique optical qualities of the material. Many of his works are based on places he has been in the wilderness. His 2016 piece, “Rustler Tank,” shown in Figure 2, is an example of this creative process. Figure 3 offers a closeup of the piece’s detailed workmanship.

The Rustler Creak piece showcases Engel’s ability to combine a variety of glass art techniques in a single work. The overall shape of the piece is the result of glass blowing. However, the surfaces and nuance are created by extensive cold work—grinding and polishing.Brian’s ability to turn images from his imagination into three dimensions is also on display with his “Coney Mine Shaft” in Figure 4. Here, Brian uses copper inlay in the glass to suggest the hidden, mysterious elements of the landscape. As with many of his pieces, he uses the art of glass to express emotional reaction to places he has visited during his life.

One thing that’s difficult to appreciate is just how challenging working in glass can befor an artist. As Brian explained in describing his work on the Crystal Gun grips, glass is an extremely unforgiving material. Unlike wood or metal, which bend,glass will only break if you press too hard in the wrong direction. With the pistol grips, for example, after dozens of hours, Brian had to grind the surface extensively. He worried about them cracking.

Brian’s expertise in cold glass work helps him get the results he’s after without too much risk of breaking his creation in the process. Cold work involves cutting, grinding and polishing glass. It requires the use of elaborate but subtle tooling. For instance, with the pistol grips, he cut a block of optical grade glass using a water-fed saw with a specially-designed diamond blade. He then ground the thin slices with a Czech glass lathe equipped with brass carving wheels with embedded diamonds.

Brian’s work hints at the paradox of glass as an artistic medium. It’s hard and unforgiving, yet fluid and appears lighter than air. Glass reveals. This is why we’re so thrilled with Brian’s work on the Crystal Gun. It’s at once a work of glass art and a working pistol. The crystal grips expose a traditionally hidden part of the gun. As a result, his work creates an intimacy with the gun. The collaboration with Brian has been a great success. We look forward to engaging with him again in the future

Brian’s work is featured on Cabot’s one-of-a-kind Crystal Gun, the first firearms which incorporates glass art into a fully functional pistol.

That’s when Cabot turned to Tom Pierce an architect and fellow committee member at The Light of Life Rescue Mission, a Christ-centered ministry providing food, shelter and life-saving programs for the poor, homeless and addicted.

“When Cabot approached me to assist in the design with the goal to reflect the three core beliefs of the company, I was excited to be part of the design team,” explained Tom. “The Trinity Checkering grew out of a collaborative, iterative design effort. It reflects the three core values and is also symbolic of the holy trinity.”

“There is precision in the ornamentation that derives from company’s strength, moral conviction, and simplicity. In the gun’s beautifully designed skin, there is also a story of this amazing company that stands behind it,” said Tom.

Tom Pierce’s story and architecture is the perfect complement to this unique design element. With more than 33 years practicing architecture, Tom has designed office buildings, residential lofts, senior care facilities, places of worship, and private homes. But Tom’s career, like many of us, was not a straight path to success but instead a journey with peaks and valleys.

“My work, my design, at times is a mystery to me. Each project is an opportunity for me to evolve and grow. By creating light and clarity in architecture, I also bring it to my life,” said Tom.

The Trinity Checkering can be found at the front and rear slide of the Jones 1911. Its elegant design creates a unique and dynamic look to Cabot’s take on the classic 1911 sidearm.

Occupation:Architect.Company: Thomas Pierce Architecture and Interior Design

Role with Cabot: Designed the Trinity Checkering on the Jones, S100 and S103 model 1911s.

Core Beliefs: “Holistic design, incorporating the heart and mind to synthesize the whole.”

Why Cabot: “Cabot is unabashed in their moral principles. It’s a Christian-based organization.”

Favorite Model: “I can’t pick a favorite. I was blown away by them all.”

Parting Wisdom: “Each new thing you do should push you to the limits of your capabilities. This creates strength.”

With a distinguished 20-year Marine Corp. career and more than 30 national records, Gunny could very well rest on his laurels. In fact, after retirement from the Marines he did just that taking a “desk job” with the NRA but it didn’t last very long.

“I got very antsy sitting behind a desk. It was tough,” said Gunny. This from a man who then took a contract guarding American cargo vessels from Somali pirates.

“I’m very competitive. It’s an overwhelming urge. Maybe it’s being a Marine. No matter what your job is. No matter what you do. You want to be the best you can be at it,” said Gunny Zins.

With that unquenched desire for competition, Gunny then joined the History Channel’s Top Gun series to out shoot 14 of America’s best shooters and become a season two finalist. “I had a great time. The cast formed a family. I really enjoyed it.”

When you speak with Gunny, close ties and relationships are a common theme. From training incoming Marine recruits to his NRA national championship competitors (he refers to the competition as a big family reunion), he speaks fondly friends, students, and competitors alike.

It was no surprise then that for Gunny joining the Cabot team as spokesman and ambassador was a decision that went beyond the quality of the guns, “It’s not just the guns. It was the company as a whole. Very welcoming, very warm,” stated Gunny.

“And the guns! The guns are impressive. The interchangeability of the parts. The tight tolerances. After seeing the shop, they have something very special,” continued Gunny. “I was impressed with how detailed they are and the work that goes into each and every gun.”

As spokesman and ambassador, Gunny Zins will demonstrate the precision of the Cabot 1911 pistol series and also work closely with Cabot to provide exclusive training and other services to the owners of Cabot 1911s.

“I’m kinda like Cabot’s poster child,” Gunny laughs. “Once they put that gun in my hand and I shot it. Wow! It was smooth. Now I’m excited to talk to people about it. To work with clients and help them with their guns. I’ve seen what’s coming next and it’s exciting.”

Gunny Zins will be representing Cabot Guns at several upcoming guns shows as well as providing training during an owners’ weekend currently planned for September 2012.

Occupation:Retired Marine. Ten-time NRA Pistol Champion. Finalist on History Channel’s “Top Shot: Season Two.”Role with Cabot: Team Cabot Shooter and Ambassador, 2012. 2013 and 2014

Core Beliefs: “No matter what your job is. No matter what you do. You want to be the best you can be at it.”

Why Cabot: “It’s not just the guns, it was the company as a whole… I didn’t see anyone who wasn’t happy to be at work.”

Favorite Model: The GI/Classic. “It looks original but it feels like a post-custom competition firearm.”

Parting Wisdom: “If you are not having fun doing what you are doing, then don’t do it.”

Interested in your own Cabot Custom? Call (724) 524-1002 or fill out the form below to begin.

© 2023 Cabot Guns All Rights Reserved

Thank you for visiting Cabot Guns. Our overreaching government has made it necessary to ask if you are over 21 years old to view our website. Also, some Europeans want us to tell you we use cookies on our website (all websites do) but we do not share any information with 3rd parties. Check out our Privacy Policy for more info.